About Us

Automating since 2007

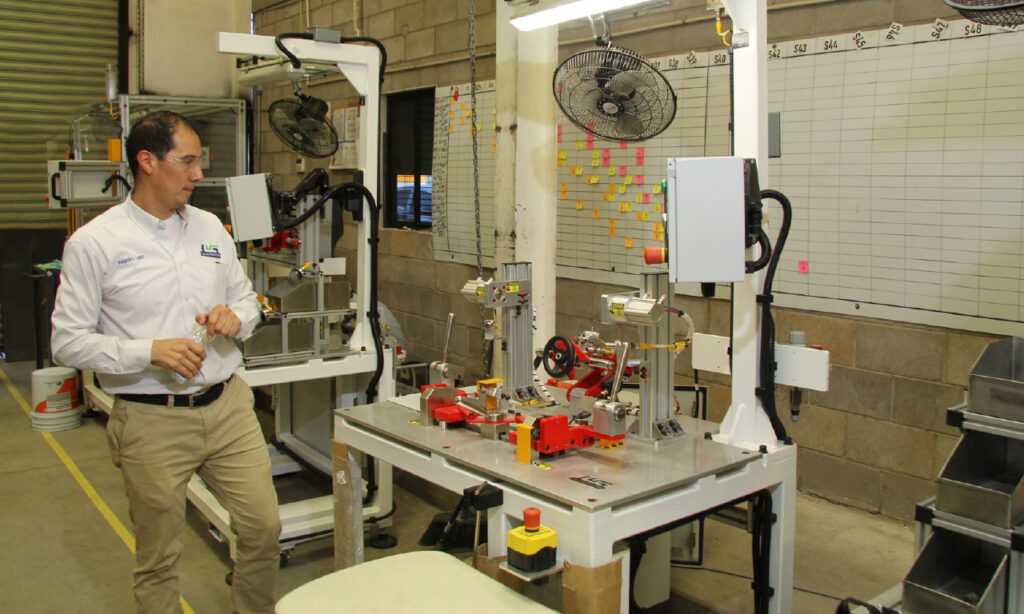

LG Automation was founded in 2007, due to the market demand for providers of Manufacturing Control Systems, by a duo of engineers offering automation services. LG Automation has shown considerable growth since then, expanding our team and our solutions portfolio. With a diverse background in successful system implementation, we have specialized in the design and manufacturing of fully automated assembly machines and work stations. Our company adds value to the customers we service, by doing whatever we can to exceed their needs and expectations, developing long-term relation- ships based on mutual trust and respect.

We are located in Hermosillo, Sonora, Mexico. Our experienced and innovative team of engineers and team builders are ready to help make your next automation project a success.

Our Clients

Employees

We understand that in a service business, our primary assets are our people and our reputation. At LG Automation, we make every effort to find the most qualified individuals for each position. With our strong commitment to client success, we have built a team of individuals passionate about problem solving and achieving effective results and we all share one common goal – the success of each client’s project. It is not enough to simply meet expectations; our goal is to set the standard for quality and service and to develop strong relationships with each and every client.

LG Automation brings together a diverse team of talented individuals across the disciplines of mechanical design, software and electrical engineering. Our team is also comprised of machinists and welders, as well as administrators who handle contracts, purchasing, accounting and quality control. We are located in Hermosillo, Sonora, Mexico. Our experienced and innovative team of engineers and team builders are ready to help make your next automation project a success.

Fully equipped for any job

We can handle your automation requirements. Our facility has a full set of tools and equipment for any job:

Mechanical Design:

- SolidWorks Workstations.

- 3D printing.

Automation:

- Design.

- Programming.

- Panel building.

- Offline Robot Programming.

Capabilities:

- HAAS VF2 CNC (30″ x 16″ x 20″).

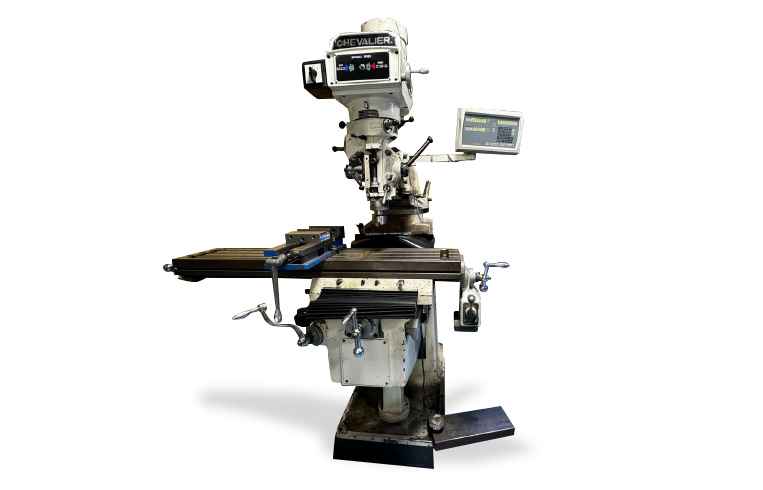

- CHEVALIER CNC (55″ x 22″ x 25″).

- CNC Lathe (Ø5″ x 15″).

- Lathes (2), Milling machines (4).

- Arc welders (3), MIG welders (1).

Manufacturing

Our facility has a full machining center, with the right tools and equipment for any job, including:

30” x 16” x 20”

55” x 22” x 25”

Ø5” X 15”

Ø14” x 55”

1X MIG Welder