We work closely with your team to fully understand your specific needs, manufacturing constraints and quality objectives, while ensuring our proposal aligns with your production goals and budget expectations.

This early-stage process identifies potential risks before they become unmanageable. We build a clear roadmap and ensure your system will meet performance and cost goals.

Our engineering team carefully analyses the project specifications and produces a comprehensive list of requirements and quality checks, while also proposing a technical solution to these requirements.

By prioritizing high-quality, readily available components, we reduce spare parts complexity and lead times for the initial shipping. We leverage our market partnerships to deliver you the best parts and ensure proper component selection.

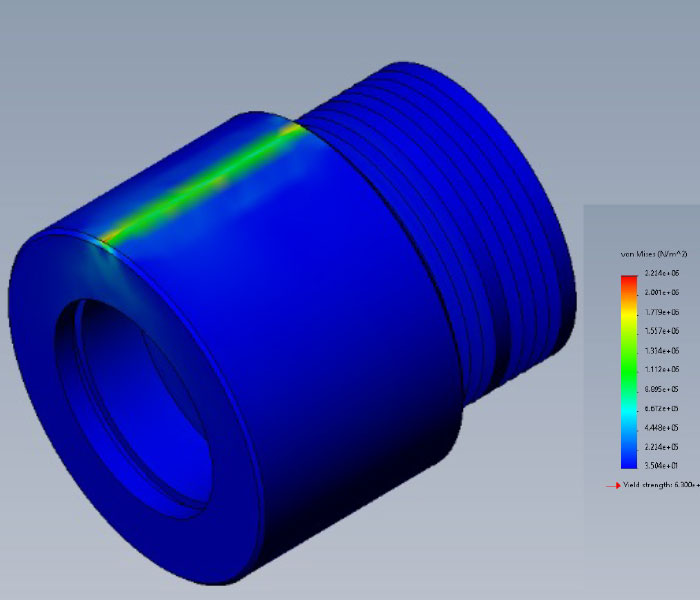

Using Finite Element Analysis (FEA) and other Computer-Aided Engineering (CAE) software, we offer digital concepts of the solution, while considering potential risks and opportunities in the design phase.

Our experienced team of engineers execute multiple virtual tests to help you launch faster and with greater confidence.

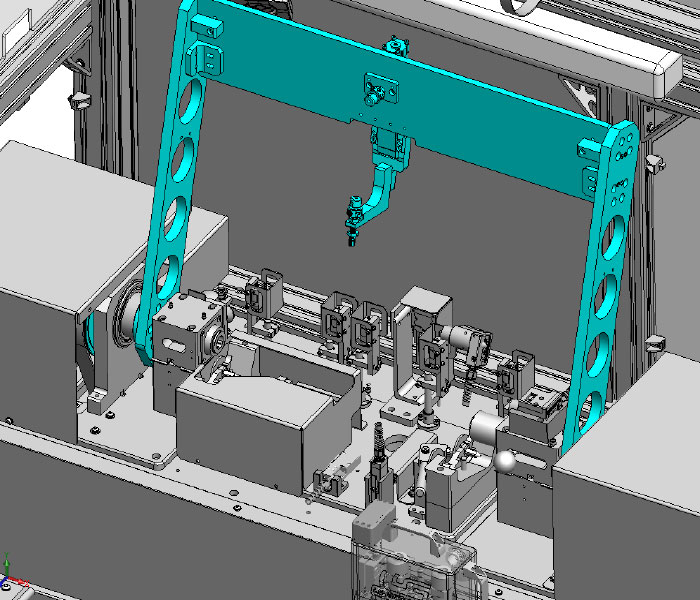

We design and test fixtures as well as CAPEX assemblies (machine structure). Our designs incorporate critical design methodologies like Design For Manufacturing (DFM) and Design for Assembly (DFA), where we analyze tolerance stack-ups and component fastening.

Our modelling process prioritizes design intent and parametrization in order to achieve a fast response time on Engineering Change Requests (ECRs), with a robust and resilient design ready for any change.