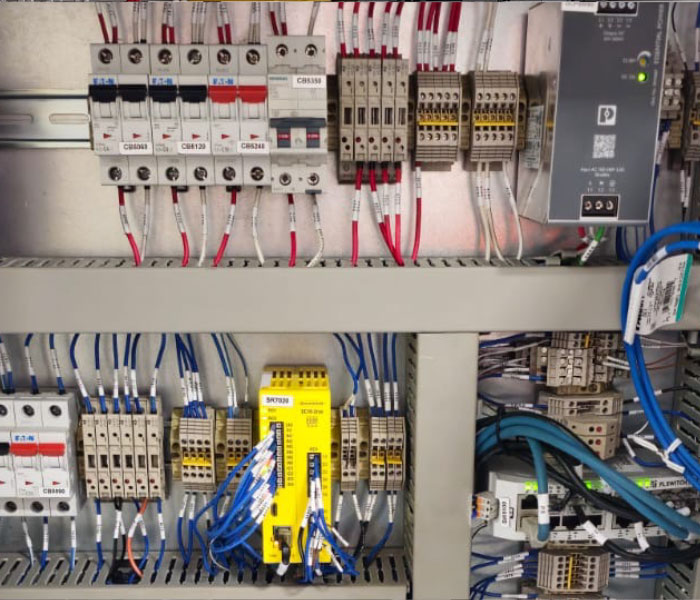

Our automation engineers handle the full commissioning of both field and control box components, as well as the programming of PLCs, motion controllers, torque controllers, safety devices and other automation hardware.

Every program is simulated and tested in our installations and in the final plant area to validate cycle time, sequence logic and error handling before product launch.

We adapt our solutions to your traceability and data exchange interfaces.

We design and implement industrial networks using protocols such as Ethernet/IP, Profinet and DeviceNet, ensuring proper data exchange and performance, while balancing repairability and cost.

Our industrial network implementations fully adapt to your standards and requirements, prioritizing spare part availability.

We develop intuitive HMI screens that both give operators clear visibility on the status of the machine, alarms and process data as well as providing the process lead the necessary tools to troubleshoot and fully understand the process status.

Our HMI implementations are developed to be fully aligned with your internal standards and requirements.

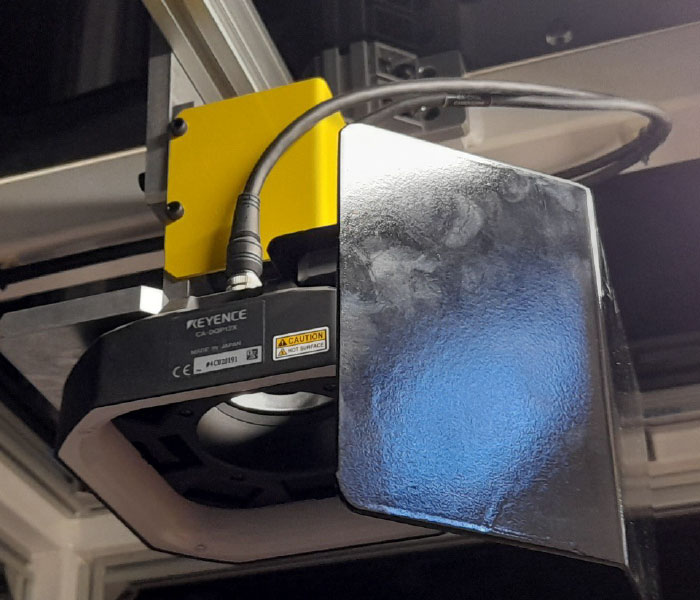

By using leading platforms such as Cognex, Keyence and others, we integrate machine vision systems to aid you in performing tasks such as presence detection, dimensional inspection, part orientation and color, as well as surface quality checks.

Our engineering team selects these components by defining proper lightning, lensing and camera selection to ensure repeatable results.